The pro version of the EcoBell4 featuring the new 4-main-needle technology is the benchmark for efficiency and resource consumption: The patented system needs just four seconds per color change for high-runner paints. The significantly shorter color changes positively impact paint and solvent losses, which are lower than any other atomizer on the market. Less waste not only cuts operating costs but is also better for the environment with fewer VOCs generated.

Universal use for all painting tasks

The EcoBell4 Pro can be used for interior and exterior painting in addition to all paint materials. The portfolio includes atomizers for both water-based and solvent-based paints in. The EcoBell4 Pro can serve both existing and new painting needs, from 4x1C painting for the base coat to 3x2C solutions for clear coat and all combinations in between.

The perfect combination: EcoBell4 and EcoProBooth

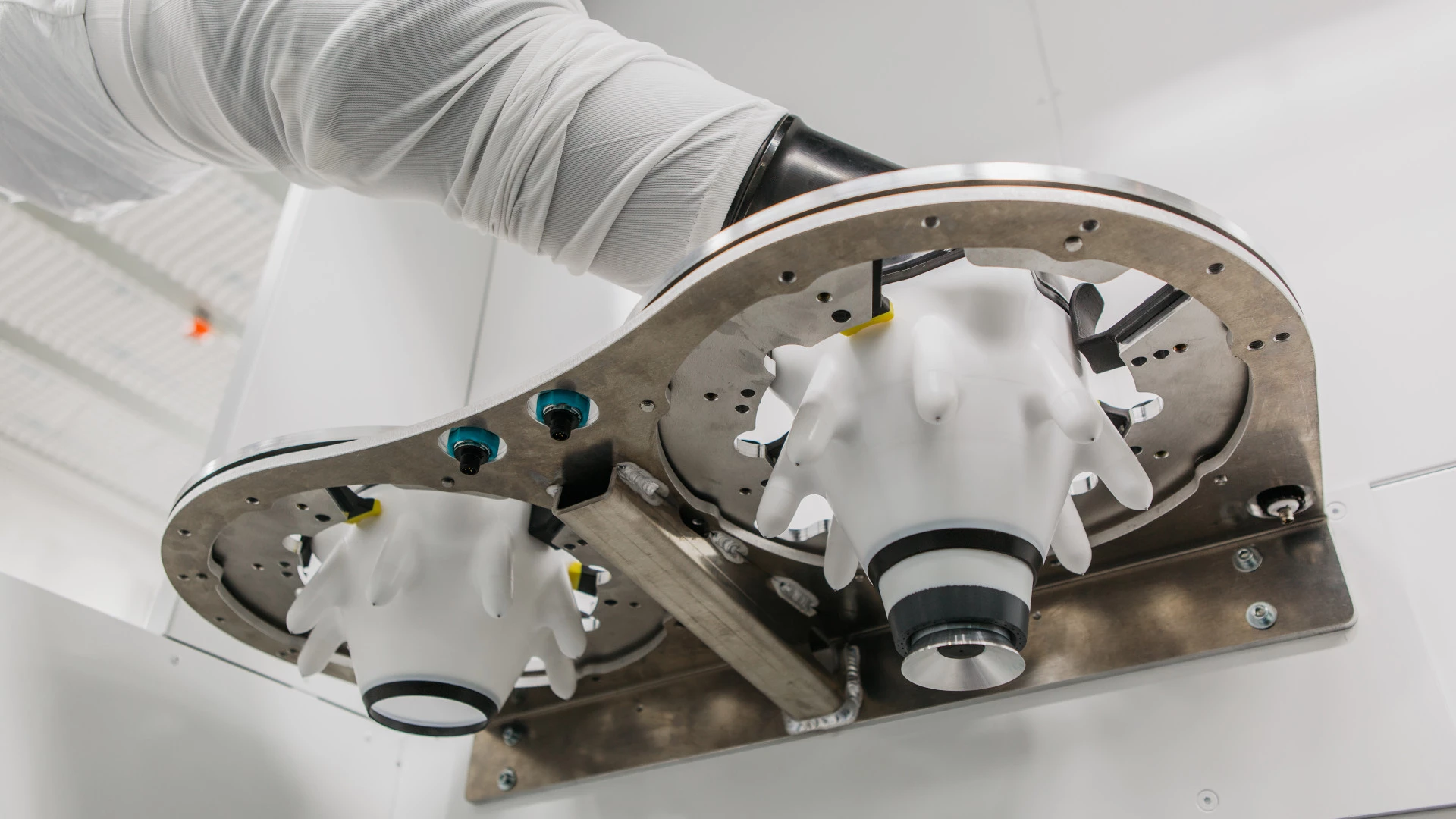

The flexibility and universality of the EcoBell4 Pro are best demonstrated in combination with the new EcoProBooth. With its smart painting booth design, the EcoProBooth combines all painting tasks in just one box, including the new, innovative EcoBell4 Pro Ux atomizer. The same bell disk/shaping air ring and external charge system handle all interior, exterior, and metallic painting (bell-bell process). The atomizer equally applies narrow spray jets inside the body and wide spray jets on the outer skin with Dürr’s usual high efficiency. Another innovation is the patented exchangeable external charge systems, which individually combine within the Pro series. Dirty electrode rings are simply discarded and replaced with clean ones in one of the four service cubicles of the EcoProBooth – without stopping the system for cleaning to take place.

Fault prevention with RFID technology

Whether in the bell disk, the shaping air ring, the turbine or the atomizer: Dürr adds RFID technology to improve processes directly in the paint booth and maintenance. RFID (radio frequency identification) is a wireless data exchange between a transponder and a writing or reading device. Since Dürr’s transponders can read and write operating data, components can store data directly and track wear.This technology provides operators with reliable information about the current condition, enabling them to make optimum use of the service life of components and plan maintenance times in advance. However, it is not just the parts needed for the maintenance work displayed. Visualization of required work steps occurs at a maintenance station with an RFID connection in assembly videos using defined sequences. Typical sources of error, such as the incorrect assignment of bell disks or air shaping rings after a break for cleaning, can also be eliminated thanks to RFID. The system detects the incompatible component when it reads out the data and warns the operator via a pop-up window even before the painting process starts. This feedback increases system availability and positively affects the first-run rate

All EcoBell4 atomizers are equipped with RFID technology. In addition, Dürr has enhanced the external charge system to make it even more efficient. Other new features include a robust rotation speed acquisition system designed for easier maintenance, a vibration sensor integrated into the robot that detects imbalances in the bell disk and turbine before they cause damage, and a protective stocking with a patented attachment concept. It reduces soiling so that at least four hours of painting are possible without cleaning the atomizer in between.