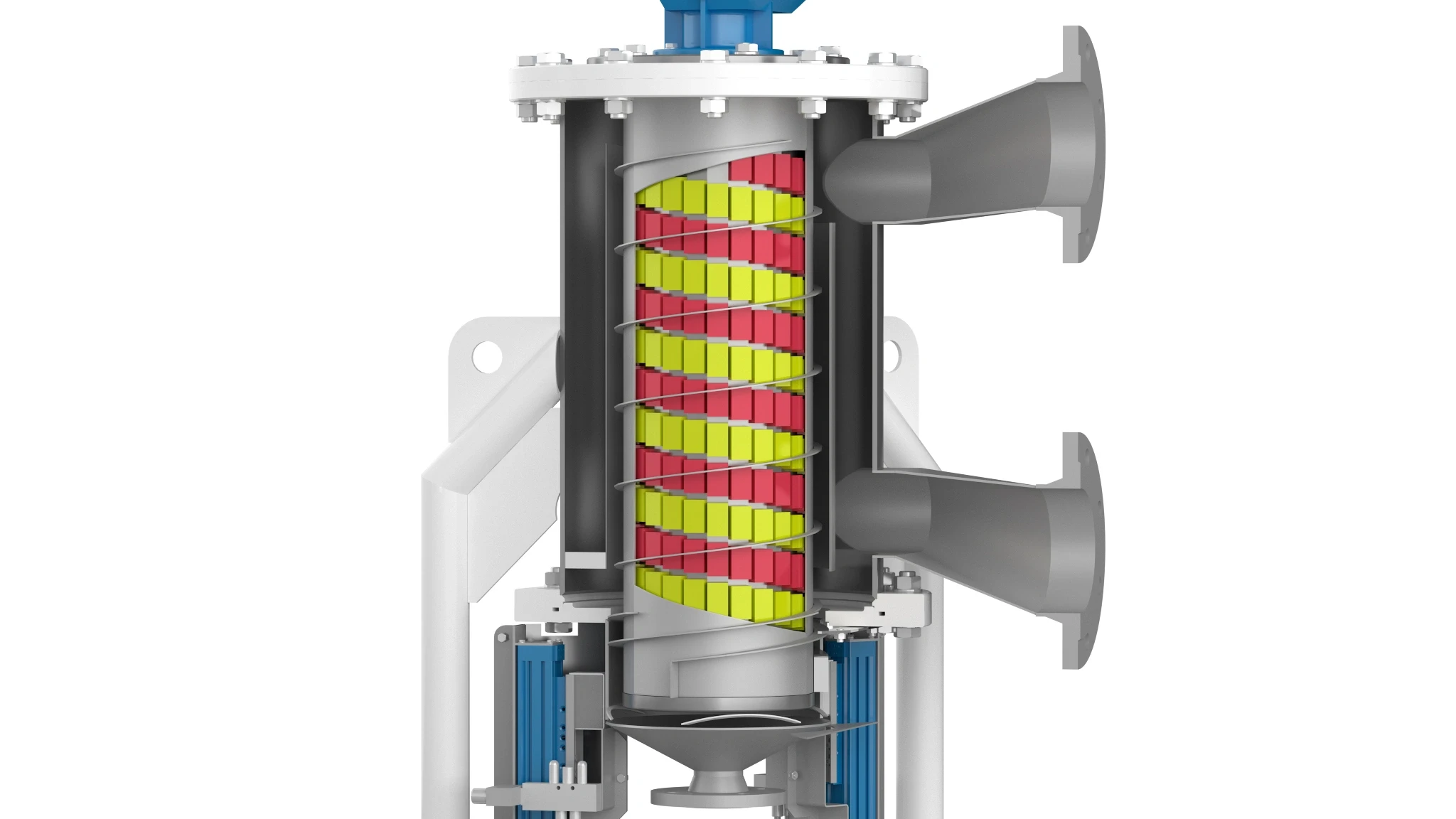

In automotive paint shops, immersion tanks filled with cleaning fluid remove grease, metallic particles, and other contaminants from car bodies during pretreatment. To ensure consistent cleaning standards, the process fluid in these tanks requires continuous cleaning, which is where the EcoMagno magnetic separator comes into play. Dürr’s patented innovation consists of a drum with neodymium magnets arranged in a spiral pattern. The drum rotation produces a steady downward movement of the separated magnetic particles towards the bottom. In this way, close to 100% of the magnetizable particles can be removed from the fluid.

Particle separation during operation

Unlike conventional solutions, EcoMagno does not need to interrupt the filtration process to remove magnetic particles. Instead, linearly moving magnets, the so-called wipers, transport the separated particles from the cylinder surface out of the vessel. This unique function, together with continuous autonomous cleaning of the system, is the only one of its kind on the market. Conventional products rely on bag filters with permanent magnets or automatic bar magnets that stop cease operation during cleaning.

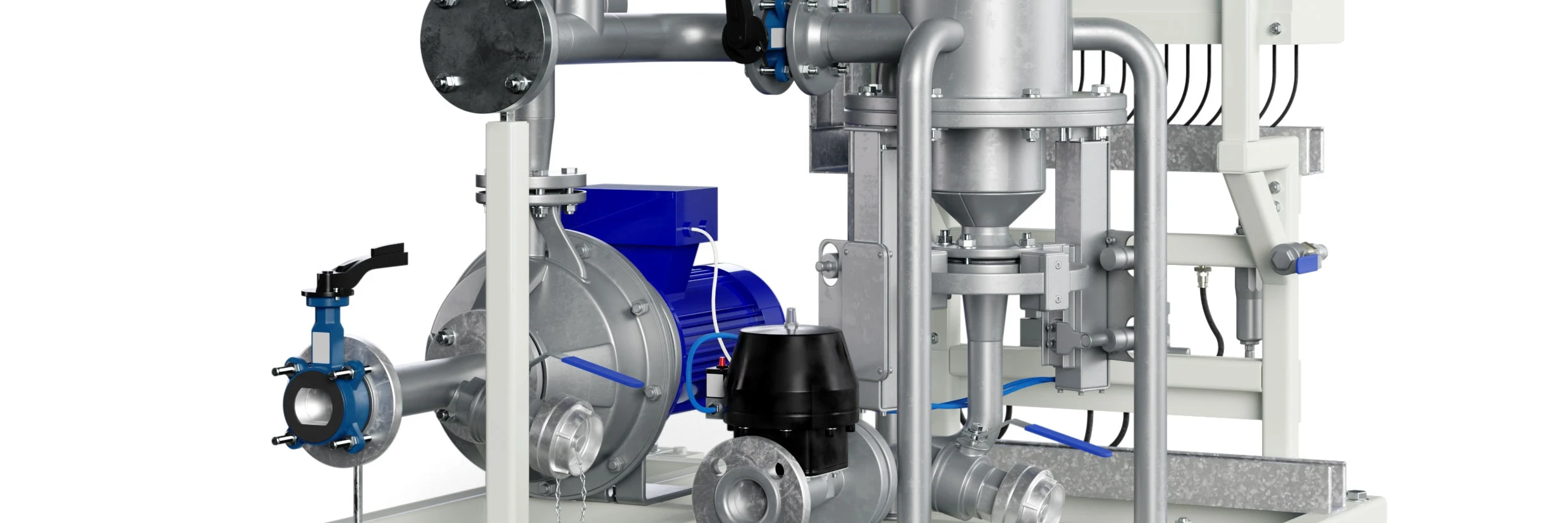

Dürr’s specially developed preinstalled unit can easily integrate into an existing system. Moreover, its design is so compact and efficient that the magnetic separator can be installed and commissioned in just a weekend requiring only an electricity supply and two flange connections.

Refinement of the magnetic separator for use in new industries

Currently, about 80 EcoMagno units are successfully used in the automotive industry. For cleaning a process tank, the magnetic separator needs a flow rate of 60 to 240 cubic meters per hour. That said, flow rates of up to 20 cubic meters per hour are often perfectly adequate in other industries, such as electroplating, machining, or the food industry. To cater to these industries, Dürr has scaled down the EcoMagno, making it suitable for a broader range of applications.