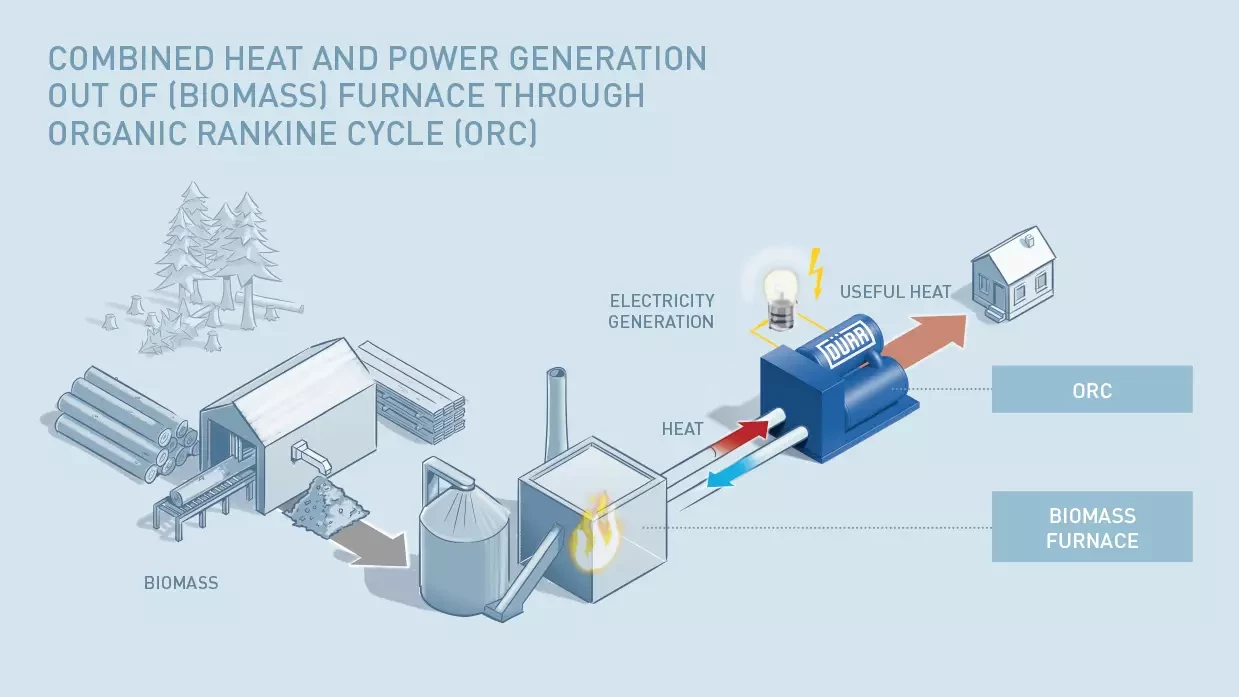

The sawmill and wood industry is constantly producing waste wood, no matter how the wood is processed. Whether bark, sawmill by-products, old wood, or industrial waste wood, the organic biomass can be used to generate energy – as the example of Heberndorfer Leistenfabrik (HLF) shows. Instead of having to dispose of 11,000 metric tons of chips each year, the company based in Wurzbach (Thuringia) puts them to use with Organic Rankine Cycle (ORC) technology. At HLF, this technology is combined with a modernized furnace system to convert various kinds of wood into heat and electricity. This means that the waste products can be used where they are produced, and where the need for the generated power also exists. It is a clean process, since the fuel is transported and stored in closed pipeline systems and bunkers.

The self-generated heat is used at HLF to heat the production halls and the administration building, while the amount of electricity generated via the ORC module covers the energy required for production and is additionally fed into the public grid. By doing this, HLF reduces its electricity costs by approximately 400,000 euros each year. “Electricity prices have almost doubled in recent years. Using waste wood for power was a strategic decision that will safeguard us against future cost increases and make us more energy independent”, explains Christian Horn, Managing Director of HLF.

Based on current electricity prices, the ORC module will pay for itself in energy savings in approximately four years. This fast return for energy infrastructure is also due to the low service and operation costs.

Dürr Cyplan offers a lucrative full service package based on a guaranteed availability for the ORC system. The system is fully assembled and tested at the Dürr Cyplan manufacturing facility, which means it only has to be connected to the heat transfer media before it is ready for operation, which can be done in two weeks. Konrad Misselwitz, Technical Director at HLF, is impressed by the concept of the Cyplan® ORC and the professional execution of the project. The system combines simple and logical operation with robust components and low maintenance requirements. It is completely standalone and can be controlled remotely. Apart from an annual service, it does not need any complicated maintenance, such as oil changes or seal replacements.

“The ORC systems from Dürr Cyplan are extremely compact, and are easy to integrate into existing energy systems and buildings,” says Project and Operations Manager Timm Greschner. This enabled the HLF furnace system to be easily extended to include the new ORC module. The high cost efficiency is further boosted by the ease of handling, the high level of automation, and the long service life of at least 15 years. This makes the system extremely economically attractive for medium and large wood processing operations.