Flexibility, scalability, software expertise, high quality, and fast installation are the challenges Dürr faces during the new plant construction in Wuhu, some 185 miles west of Shanghai. Chery sums up its requirements for the new plant by stating it wants it to be a “highly intelligent paint shop.” It will paint numerous vehicle categories, from typical bodies to SUVs. The paint shop is designed to allow future expansion and can also handle two-tone painting. The plant will be ready for operation within eight months and will then complete bodies at a rate of up to 60 per hour.

Extensive ensemble of robots

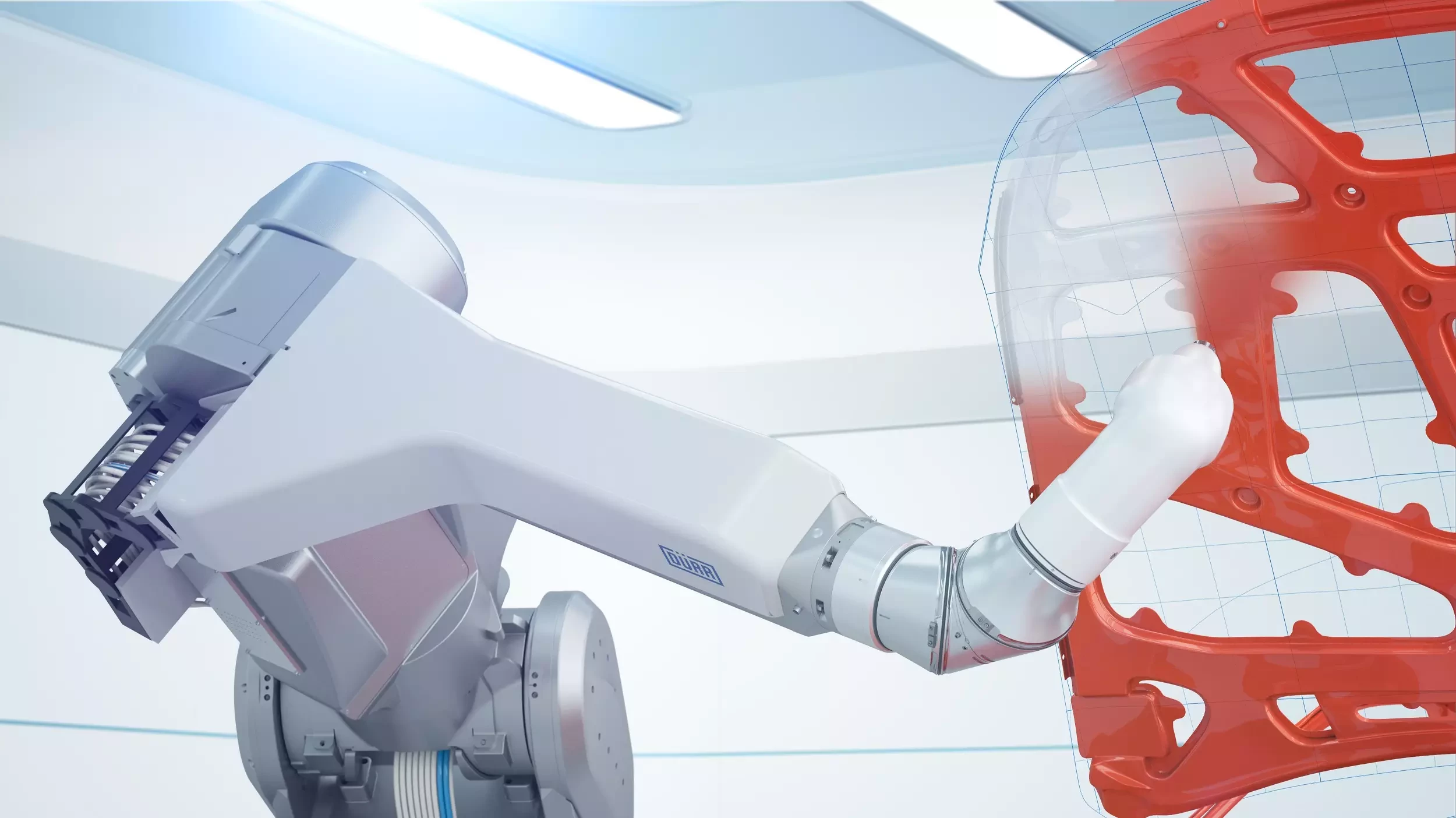

Dürr is equipping the new paint shop with an extensive ensemble of robots. The 92 painting robots will include 16 EcoRP E043i and four EcoRPL043i. These robots, which are very mobile because of their seventh axis, can easily reach even difficult-to-access places in the body interior. EcoBellCleaner D2 devices clean the high-speed rotary atomizers from the outside within the cycle time. Color changes and color channel cleaning inside the atomizer occur in parallel, so the system is ready for the next paint job after 15 seconds. In addition, there are 38 EcoR30L 16i and EcoRS 16i sealing robots responsible for all bonding and sealing processes and four compatible cleaning robots.

Many modules from the DXQ software family

The “highly intelligent paint shop” Chery desires will become a reality in combination with DXQ software products. Dürr will use DXQcontrol for higher-level control of the plant. The software seamlessly tracks the life cycle of each body. The DXQequipment.operation human-machine interface visualizes and monitors individual processes from any device. DXQquality.management connects process monitoring with vehicle details, creating a seamless data record for each vehicle. And DXQequipment.maintenance logs when individual components like pumps, valves, or filters need to be maintained. In addition, numerous other DXQ portfolio modules will guarantee data-based and fully automated paint shop operation.

Energy efficiency through intelligent air management

In addition to plant flexibility and the networking of all components, energy efficiency is important to Chery. EcoSmart VEC regulates the ovens’ fresh and exhaust air control, which are the biggest energy consumers in the coating process alongside the painting booths. Intelligent air management adjusts the energy supply to the actual need and reduces it in partial-load operation, saving not only energy but reducing CO2 emissions.

Chery is China’s top car exporter

Car manufacturer Chery was established in 1997 and is China’s top car exporter. According to their figures, Chery has already sold over nine million vehicles in more than 80 countries and regions. In 2019, the company opened a development and design center in Raunheim near Frankfurt, Germany, to gain a foothold in the European market.