With a view to the market launch of the new Urus super SUV, Lamborghini modernized its long-established plant within just 18 months during ongoing production. Not only was the production space doubled from 80,000 m2 to 160,000 m2, but also the overall capacity to 7,000 vehicles annually. For this strategically important project for the future of the brand, Lamborghini entrusted Dürr with developing new production lines for complete vehicle assembly. This is based on a forward-looking layout in which each area can be used flexibly. That allows the line configuration to be modified at any time following installation, in other words it remains adaptable to changing requirements.

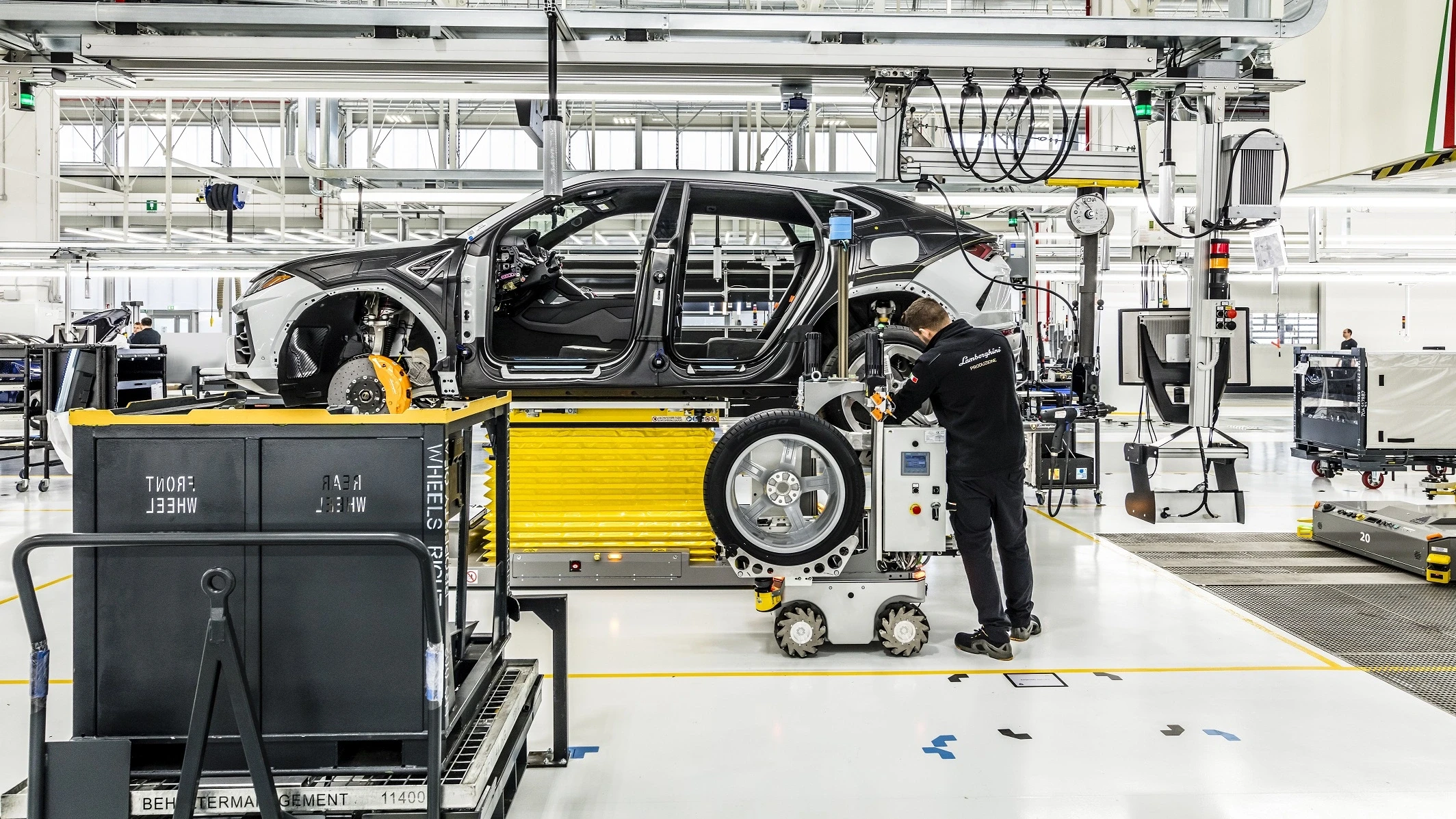

AGV fleet in various sizes

The conveying system with AGVs, specifically developed by Dürr for the Urus, guarantees a high degree of flexibility. The AGVs move individual components and bodies separately instead of one after another in a linear conveyor system as it has been the case up to now. They also run without rails, are freely programmable like robots, and can be controlled flexibly. This means that future model series can also be manufactured on existing lines, since they can be changed over quickly in order to be appropriate to new market scenarios and varied production requirements. The AGVs at Lamborghini come in three different sizes and are suitable for line feeding tasks, the processes in the main line, and for subassembly and powertrain operations.

Ergonomically optimized workstations

In addition to the AGVs, Dürr installed further technologies that also meet the most demanding standards for ergonomics in the workplace. These include loading carriers (body on AGV), unloading devices (car from AGV), rotating and vertical adjustable carriers for body transport and lifting, as well as slat conveyors with a lifting table for moving the vehicle into an ergonomic position.

Overall control of the project on behalf of the Dürr Group rested with CPM, its Italian subsidiary specializing in final assembly. CPM and Lamborghini were already working hand in hand on layout design for conveyor technology, assembly lines, marriage stations, trim lines, and the end-of-line area. CPM was supported by its German colleagues from Dürr Assembly Products, which among other things supplied the x-road roll/brake test stand and adjusted it precisely to the Urus.