ARA Rhein purifies around six million liters of waste water every year. The company is the central waste water disposal service provider in the canton of Basel, one of the world’s most important centers for chemical and pharmaceutical production. The waste water produced there is a textbook example of how varied and everchanging the pollutant load of waste water merging from various chemical-pharmaceutical industrial plants can be. Depending on the respective composition of the waste water, the exhaust air to be treated also varies. ARA Rhein’s biofilter plant was no longer flexible enough to react to these variations, creating a solvent smell in the area. “Unlike foul odors from municipal purification plants, a chemical substance odor is not only annoying to humans, but also unsettling,” explains Peter Müller, Managing Director of ARA Rhein AG. In addition, emission limits were briefly exceeded because the existing sludge incineration system was no longer large enough to process what was needed. It was against this background that ARA Rhein looked for a suitable solution.

Technically sophisticated design

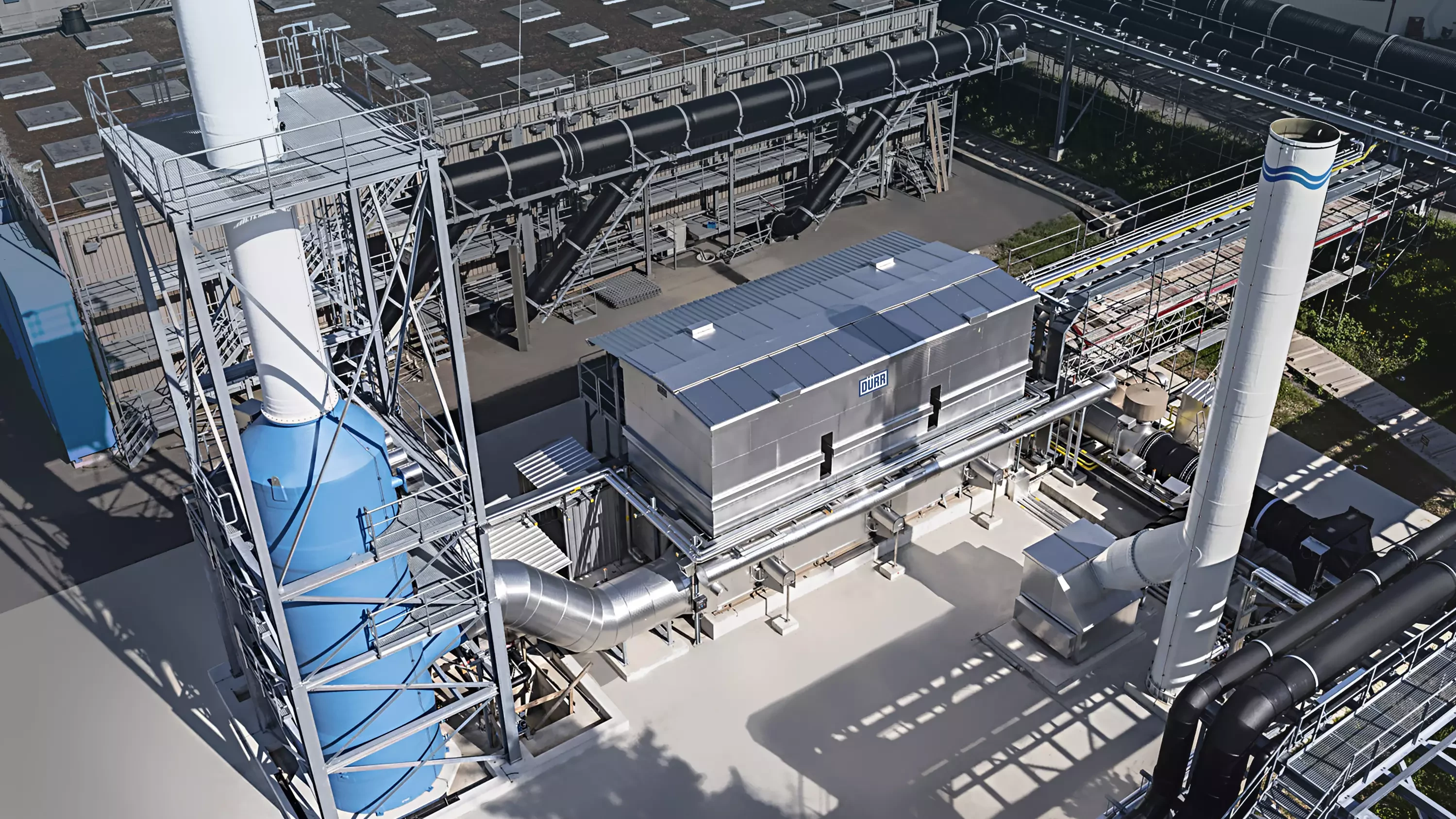

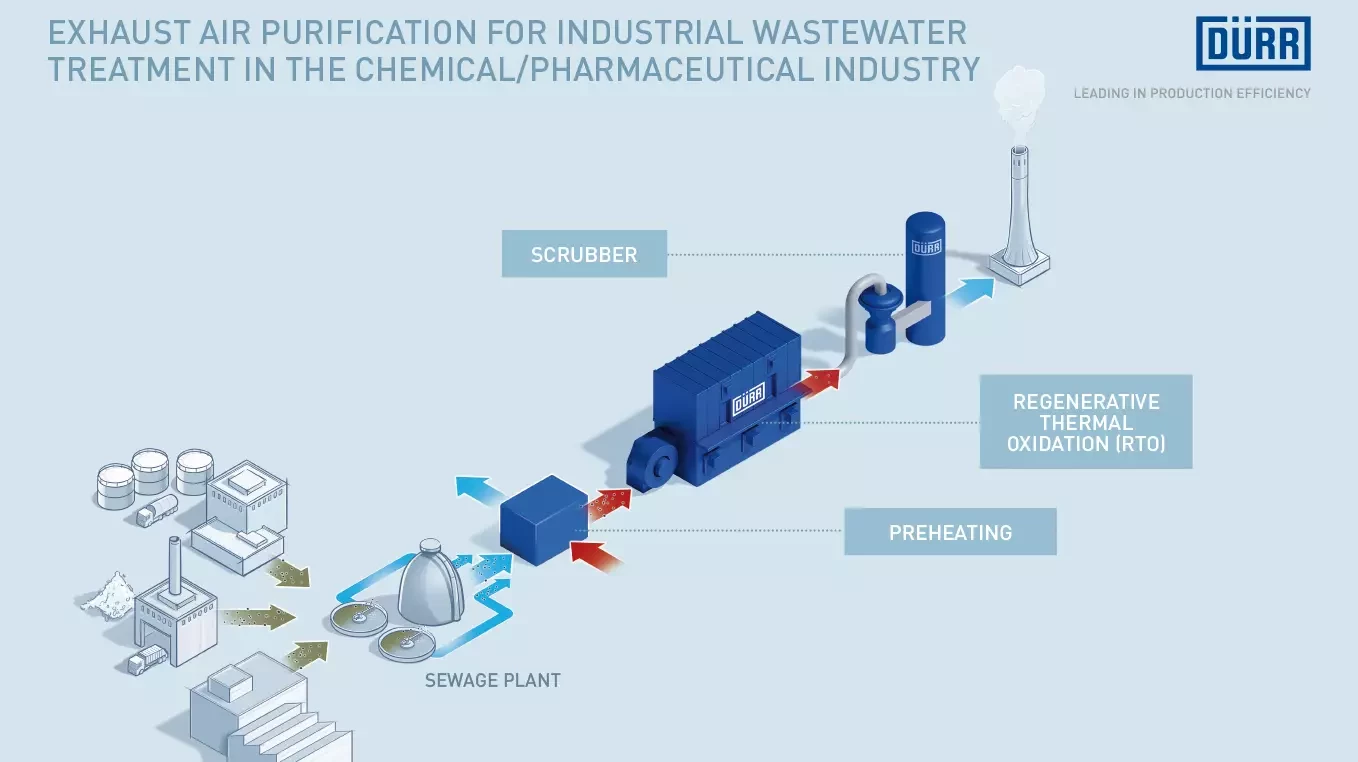

Regenerative thermal oxidation (RTO) is becoming increasingly popular for the treatment of exhaust air from industrial processes. This technology was ideal for ARA Rhein, however with a much more sophisticated technical design for the plant than the one necessary for many other industries. “Waste water from chemical, petrochemical, and pharmaceutical industries typically contains a multitude of hydrocarbons, sulfurous, and inorganic compounds. The exhaust air that escapes from these compounds is highly corrosive and would corrode the materials com-monly used in air pollution control plants and destroy them in the long term,” says Markus Dertinger, Global Customer Director at Dürr. That is why Dürr planned and built a multi-stage Ecopure® RTO system with a corrosion-proof design.

High energy efficiency through heat recovery

The humid air produced by water treatment plants is dried during the first stage to prevent condensation in the RTO system. This is done by first routing the air through a droplet separator and then heating it in a heat exchanger. Dürr favors this particular design of heat exchangers in accordance with the individual requirements of a purification plant because the right construction type and chemical composition have a significant influence on the choice of materials and the necessary maintenance intervals, and therefore on the plant availability.

The predried air then reaches the next step, thermal oxidation, via a fan. The com-bustion process that takes place there produces acid that corrodes the material from which the plant is constructed. Corrosion-proof special materials protect the plant against this danger. They consist of a combination of high-grade stainless steels with different coatings. The design of the Ecopure® RTO enables various materials and coatings to be used so that the system can be optimally adapted to different pollutant loads.

To burn all the organic compounds – and therefore also the odorous substances – the contaminated exhaust air must be heated to at least 850°C. The high tempera-ture is achieved with minimal use of primary energy because an integrated ceramic heat exchanger already heats the exhaust air to 820°C. A natural gas burner is only used for the remaining 30°C to achieve the operating temperature. “The process is very energy efficient since the heat is recovered from the hot, purified air to heat the cold, unpurified air,” explains Dertinger.

In the last stage of the exhaust air treatment process, a flue gas scrubber removes all the acidic pollutants that have formed during oxidation. Ultimately, the system achieves a 99.9% destruction efficiency. “The RTO system has fully met all expec-tations. We’re not getting any more complaints about unpleasant odors and are complying with the legal limits. The system has a high level of availability and so far has not had any unscheduled downtimes. On top of this, the operating costs are as low as Dürr told us they would be,” says Müller, positively summing up the first year after the system was put into operation.